Get solutions that meet your industry's specific needs

Versatile solutions for the special needs of different industries

RIECCO can offer a full range of services, from engineering to support services and management.

Feasibility Studies

Feasibility studies and technical and financial consulting work, from the conceptual analysis of the opportunity to the necessary definition to pin down the project ..

FEED – Front End Engineering and Design

Detailed analysis of a project in which, from the Basic Engineering of the licensed units and Open-Art, the main processes are defined, the technologies are selected.....

OBCE – Open Book Cost Estimate

A process that is carried out from a FEED and in which the customer and the engineering work jointly and transparently in defining the total costs of a project.

PMC – Project Management Consultant

Support to customers in the project direction and in the coordination of the different interfaces to bring down the costs and to finish the execution of the project as a whole.

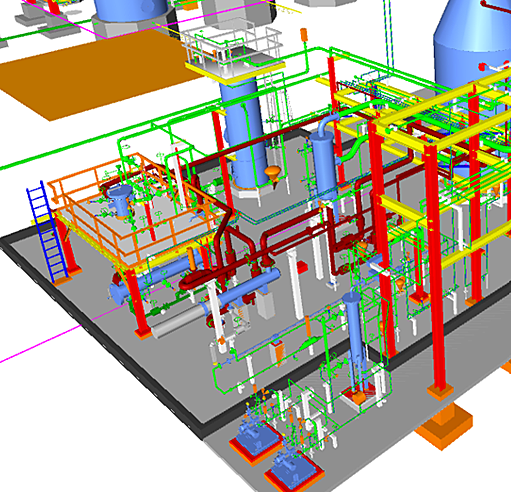

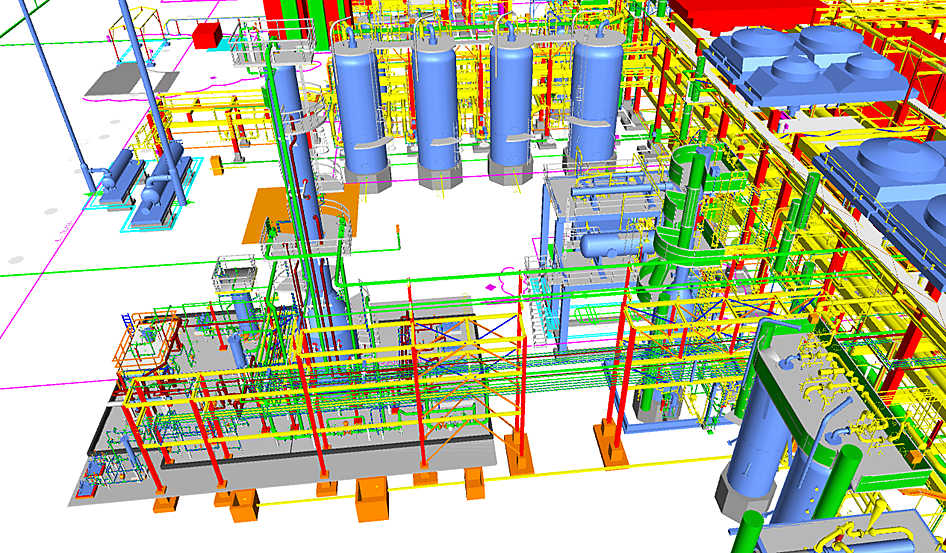

Detail Engineering

Detail Engineering, contemplating all the disciplines of an industrial project.

• Extended Basic Engineering

• Stress Analysis

• Technical / HAZOP Studies

• HTRI Analysis (Thermal Analysis)

• HAZOP Study & Due Diligence

• Process Dynamic Simulation

• Piping Stress Analysis

• 3D Model , FEA & CFD Analysis

• Static Equipment design Analysis

• Vibration studies for Equipment and structures

• Engineering studies for existing foundation and structures

• ETAP studies (Transient, Harmonic, Motor & current analysis etc.)

• Constructability Reviews

• Plant Revamp and debottlenecking Studies

• Plant and Equipment Relocation studies

• Extended Basic Engineering

• Stress Analysis

• Technical / HAZOP Studies

• HTRI Analysis (Thermal Analysis)

• HAZOP Study & Due Diligence

• Process Dynamic Simulation

• Piping Stress Analysis

• 3D Model , FEA & CFD Analysis

• Static Equipment design Analysis

• Vibration studies for Equipment and structures

• Engineering studies for existing foundation and structures

• ETAP studies (Transient, Harmonic, Motor & current analysis etc.)

• Constructability Reviews

• Plant Revamp and debottlenecking Studies

• Plant and Equipment Relocation studies

Procurement Services

Management of purchases, inspection, activation, traffic and supply, in a department devoted exclusively to supplying equipment and materials under optimal conditions of price, term and quality, from anywhere in the world.

We Engineer to internationally recognised and certified standards

Years Of Experience

+

Completed Projects

+

QEHS - Quality, Environment , Health & Safety

QEHS is one of the fundamental pillars of RIECCOs’ strategy.

Employees and procedures have a key role in the quality aspects of the Company’s performance.

RIECCO relies on an excellent team so that the Company can tackle any challenge it faces and attain its objectives sustainably, responsibly and with the quality standards required by the market.

RIECCO has Integrated Management System in accordance to ISO , focused mainly on continuous improvement and learning based on the successes and failures that occur during our day-to-day activities. This system is a fundamental element in the innovation process and encompasses the entire value chain, including suppliers and subcontractors.

RIECCO has Integrated Management System in accordance to ISO , focused mainly on continuous improvement and learning based on the successes and failures that occur during our day-to-day activities. This system is a fundamental element in the innovation process and encompasses the entire value chain, including suppliers and subcontractors.

Today RIECCO has following prestigious Projects:

- PMC Services for Nitrogen Generation Unit

- Detail Engineering Works for 3MW Steam Turbine replacement – India

- Expediting Services for Process PUMPS (200 Nos) for KSA project.

- Due Diligence of Ammonium Nitrate PLANTS-Egypt.

- Pre Project-Services for 1 MMTPA Green Ammonia Plant – India.

- Three Year General Engineering Services (GES) contract with Two major Petrochemical Companies in KSA.

- PMC for a Grassroot 1500 MTPD Ammonia plant (successfully commissioned recently).

- Detailed Engineering Services for Formaldehyde Project

- Detailed Engineering for Urea Formaldehyde Concentration (UFC-85) Project

- EPCM Services for Ammonium Bicarbonate Project

- PMC for Green Ammonia Plant (300 MTPD)

- ETAP Transient Stability Analysis Study for a Petrochemical complex

- Detailed Engineering for a chemical pilot plant

- PMC for Ammonia Storage Tanks (2 x 5000 Te) & Associated Facilities.

- PMC for Urea Plant & Bagging Plant

- Basic and Detailed Engineering for CO2 Export line

- Phosphoric Acid Storage System

- EPC services for Geotech, Topography survey and EIA Studies

- Detail Engineering Package (DEP) For Sodium Sulphate Plant

- Engineering and Procurement services for Side Stream Filter installation for Cooling water system

- PMC Services for Ammonia Storage Tanks (2 x 30,000Te) with associated facility.

Our extensive resume is comprised of over 3,500 projects completed

We always help the industry improve its environmental and social performance

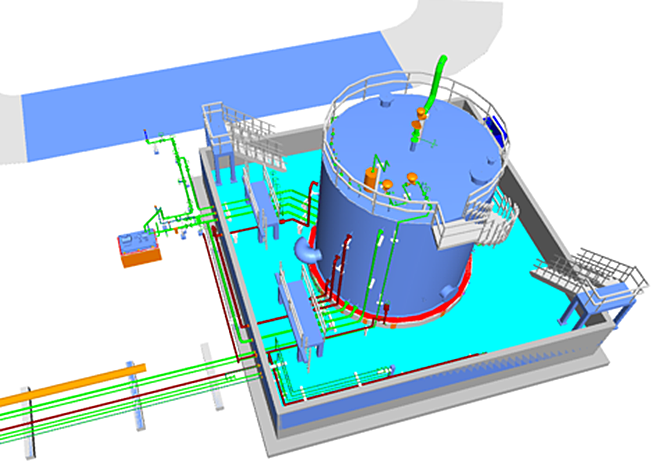

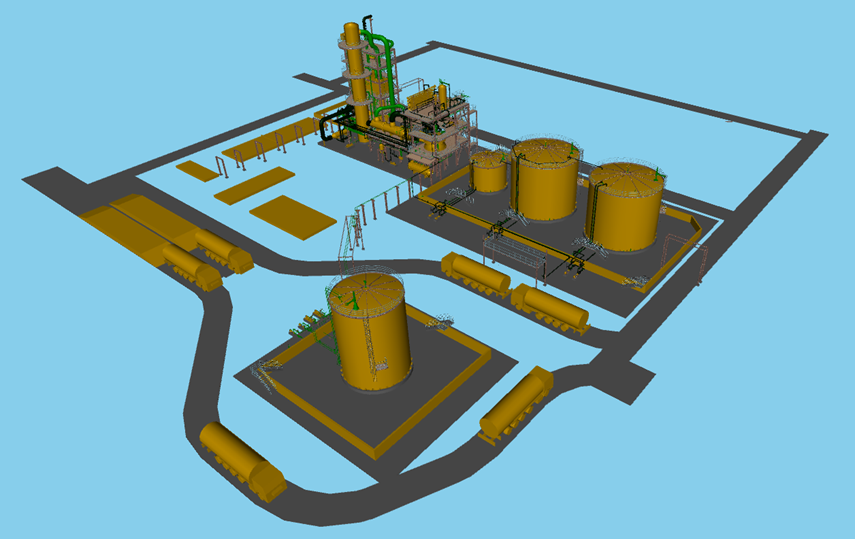

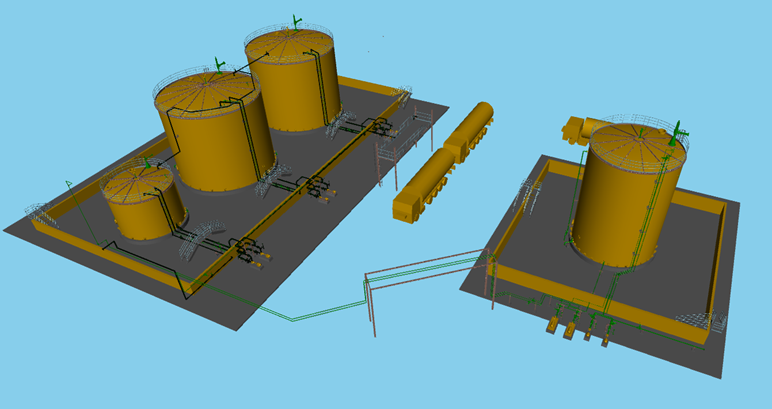

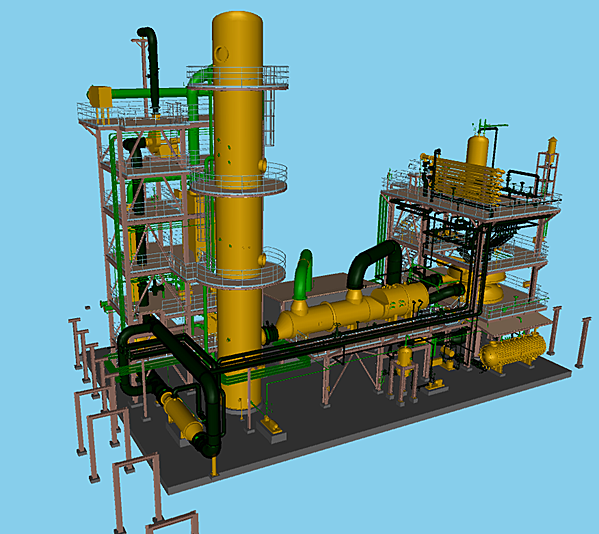

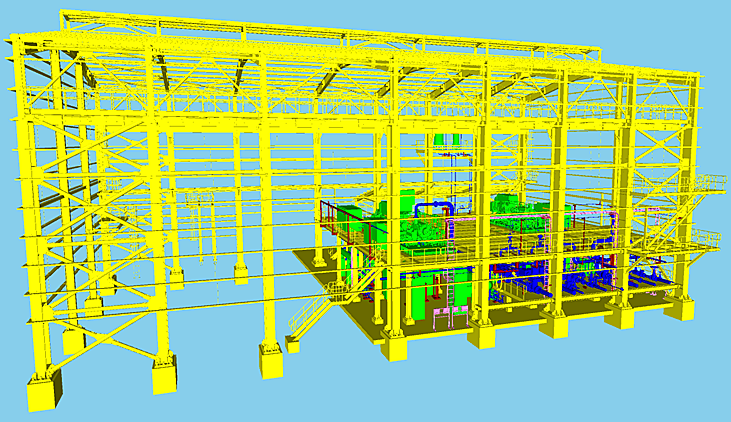

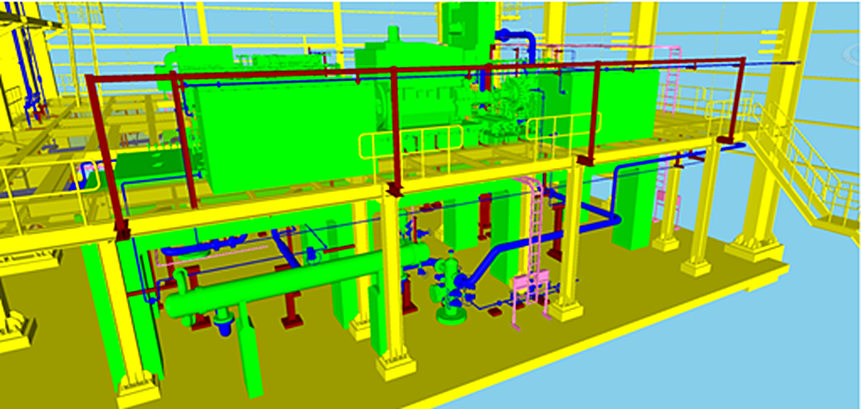

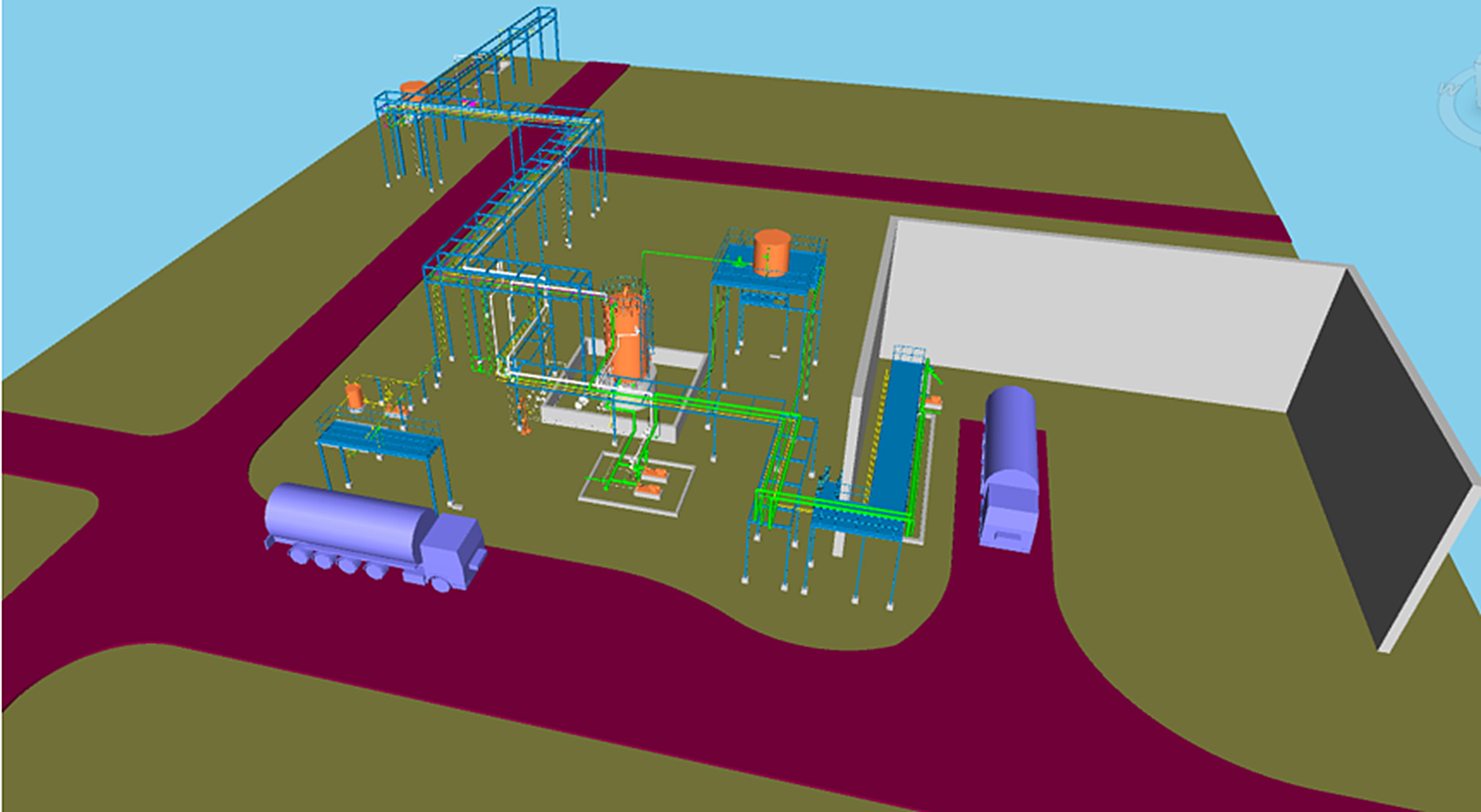

Molten Ammonium Nitrate Storage

Project: Molten Ammonium Nitrate Storage

Scope of Work: Detail Engineering Package (Process, Mechanical, Civil&Structural, Piping, Electrical, Instrumentation) and 3D Modelling for Ammonium Nitrate Storage tank system.

KSA Client Base

Global Client Base