We focus on the entire process of the project, concept through completion

We are a leading company, serving clients around the globe

RIECCO Completed more than 250 Projects with our JV man hours ranging between 500 to 25000 per project for clients in KSA and Globally with services like

Extended Basic Engineering, Detailed Engineering, Feasibility studies, DPRs, Project Management services, Procurement services, HAZOP studies, As-built and

technical studies.

Extended Basic Engineering, Detailed Engineering, Feasibility studies, DPRs, Project Management services, Procurement services, HAZOP studies, As-built and

technical studies.

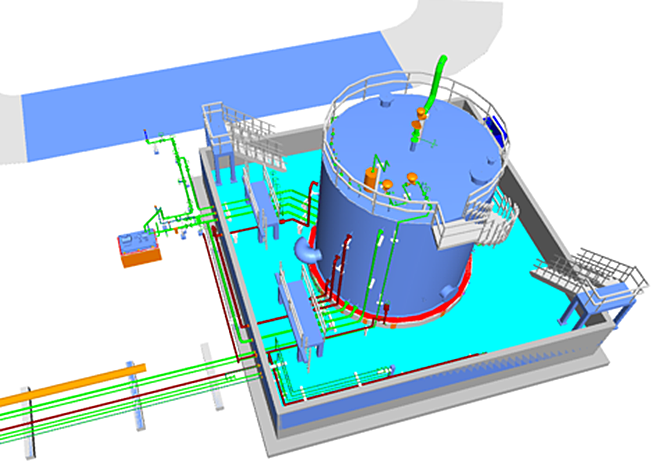

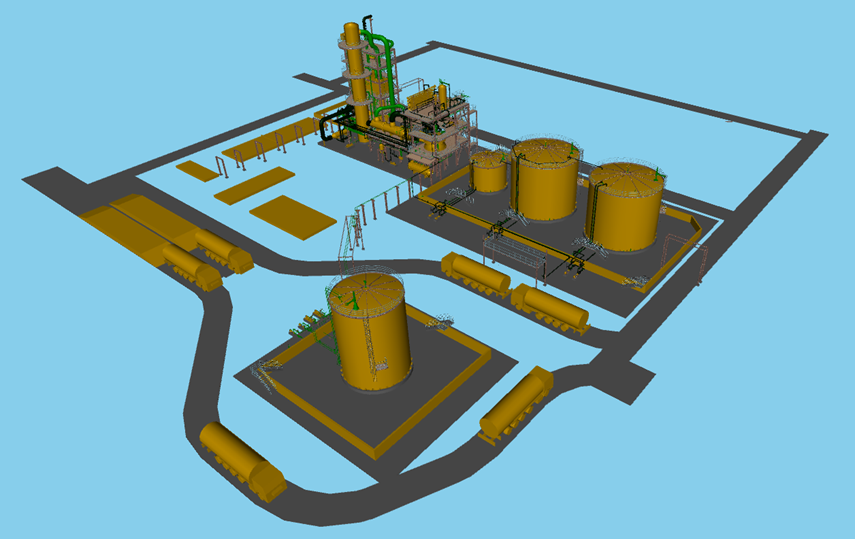

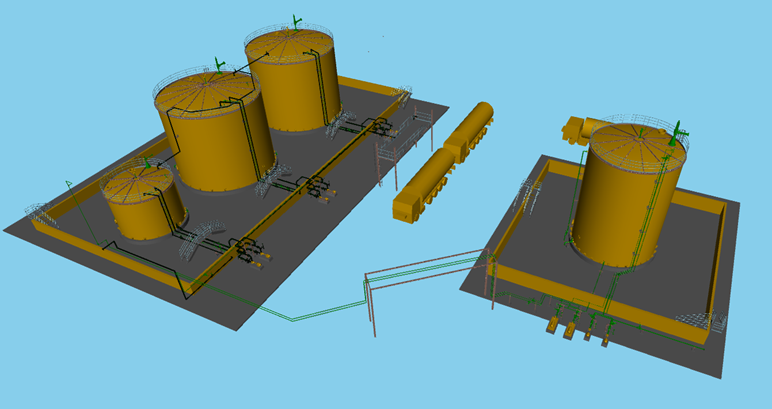

Molten Ammonium Nitrate Storage

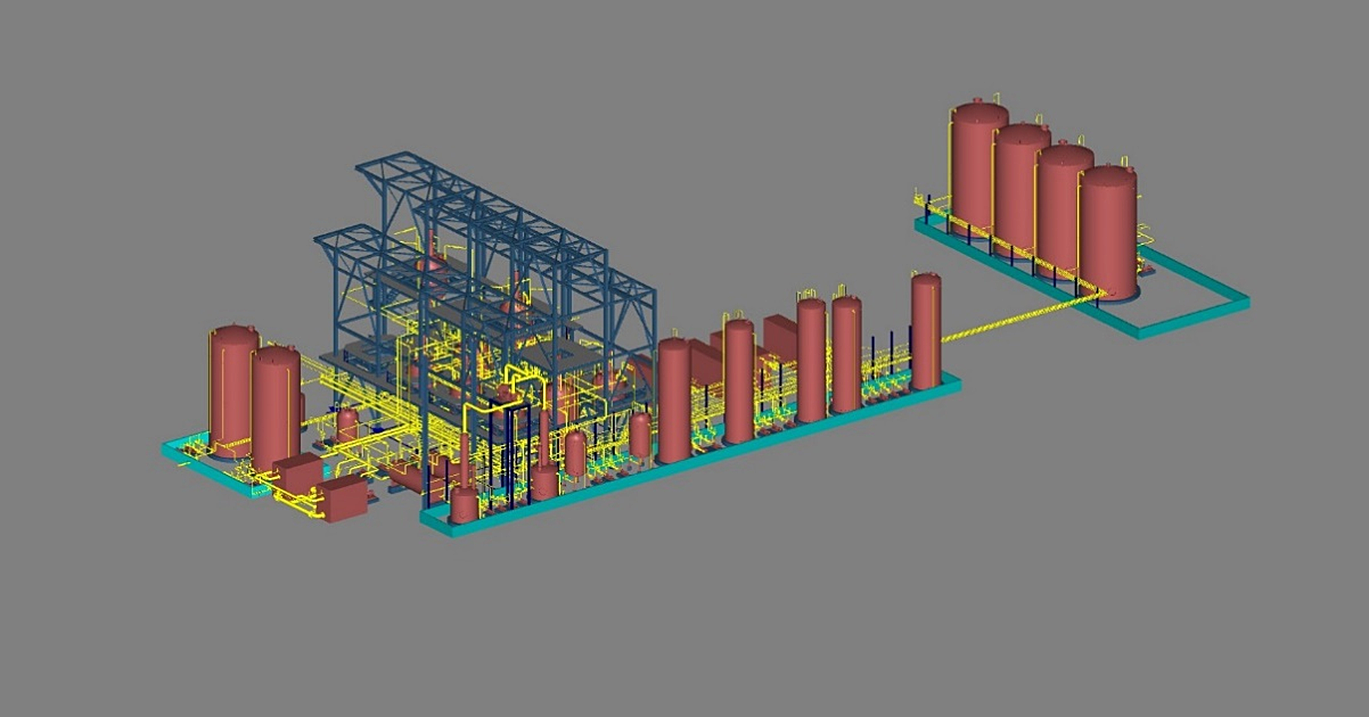

Project: Molten Ammonium Nitrate Storage

Scope of Work: Detail Engineering Package (Process, Mechanical, Civil&Structural, Piping, Electrical, Instrumentation) and 3D Modelling for Ammonium Nitrate Storage tank system.

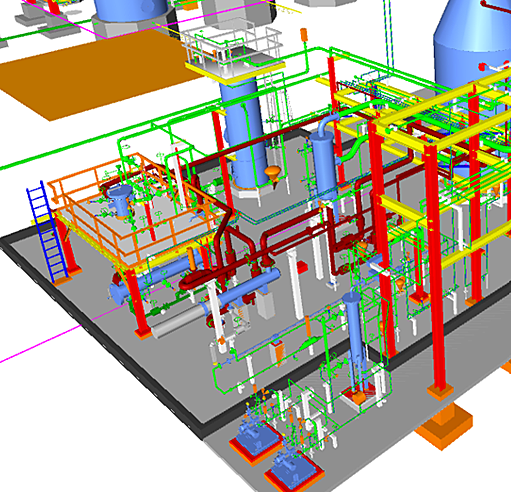

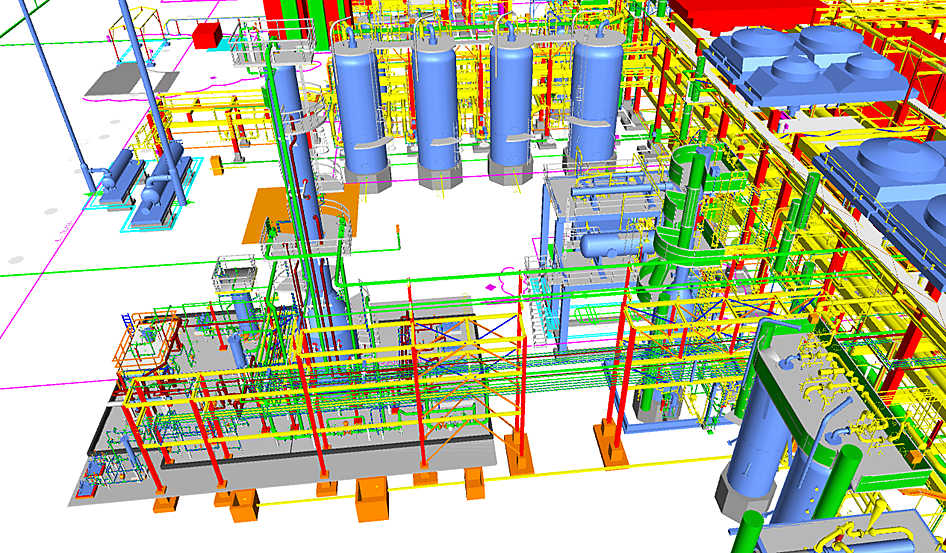

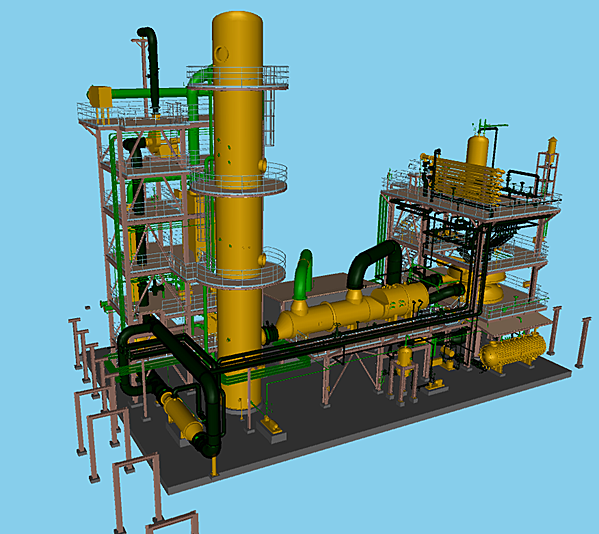

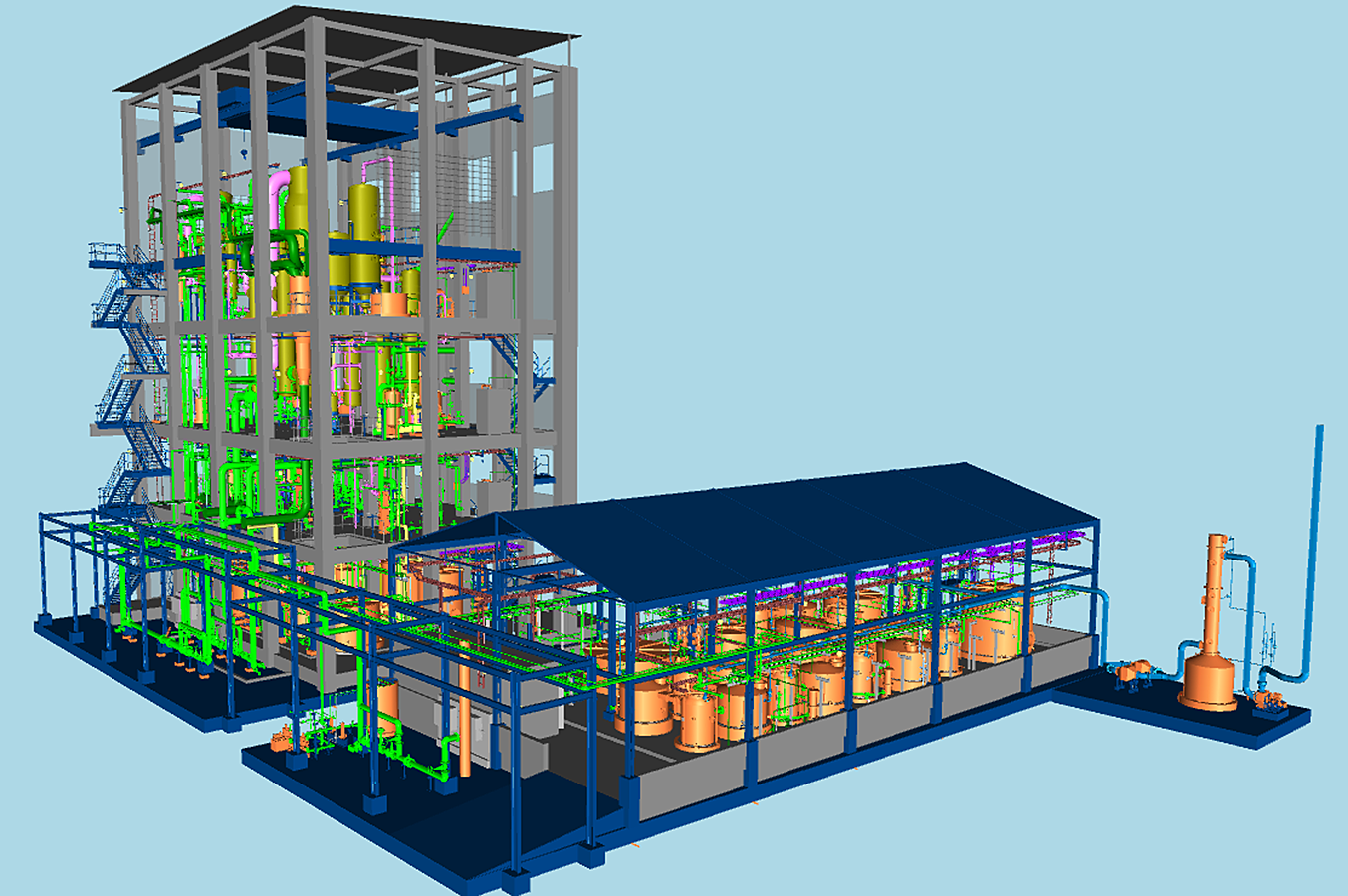

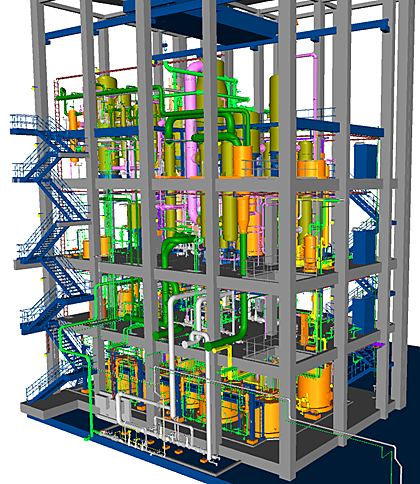

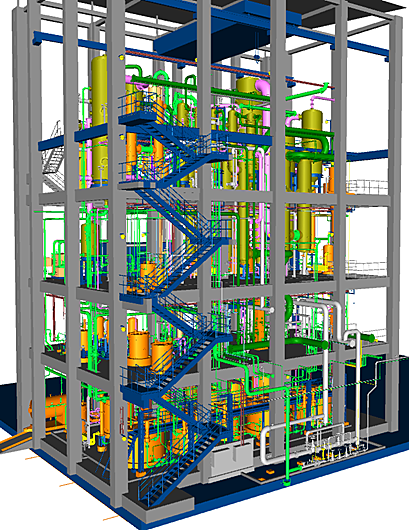

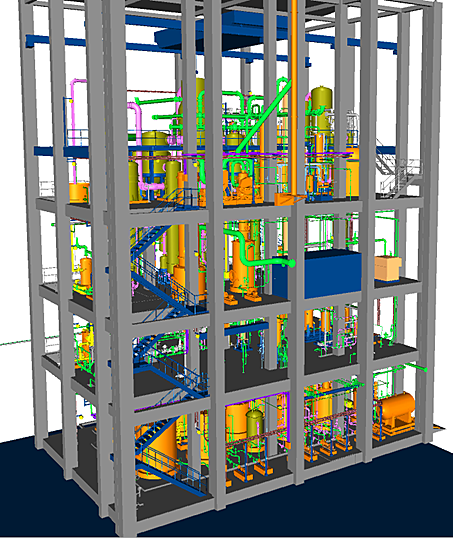

Sulphonated Naphthalene Formaldehyde (SNF) Plant

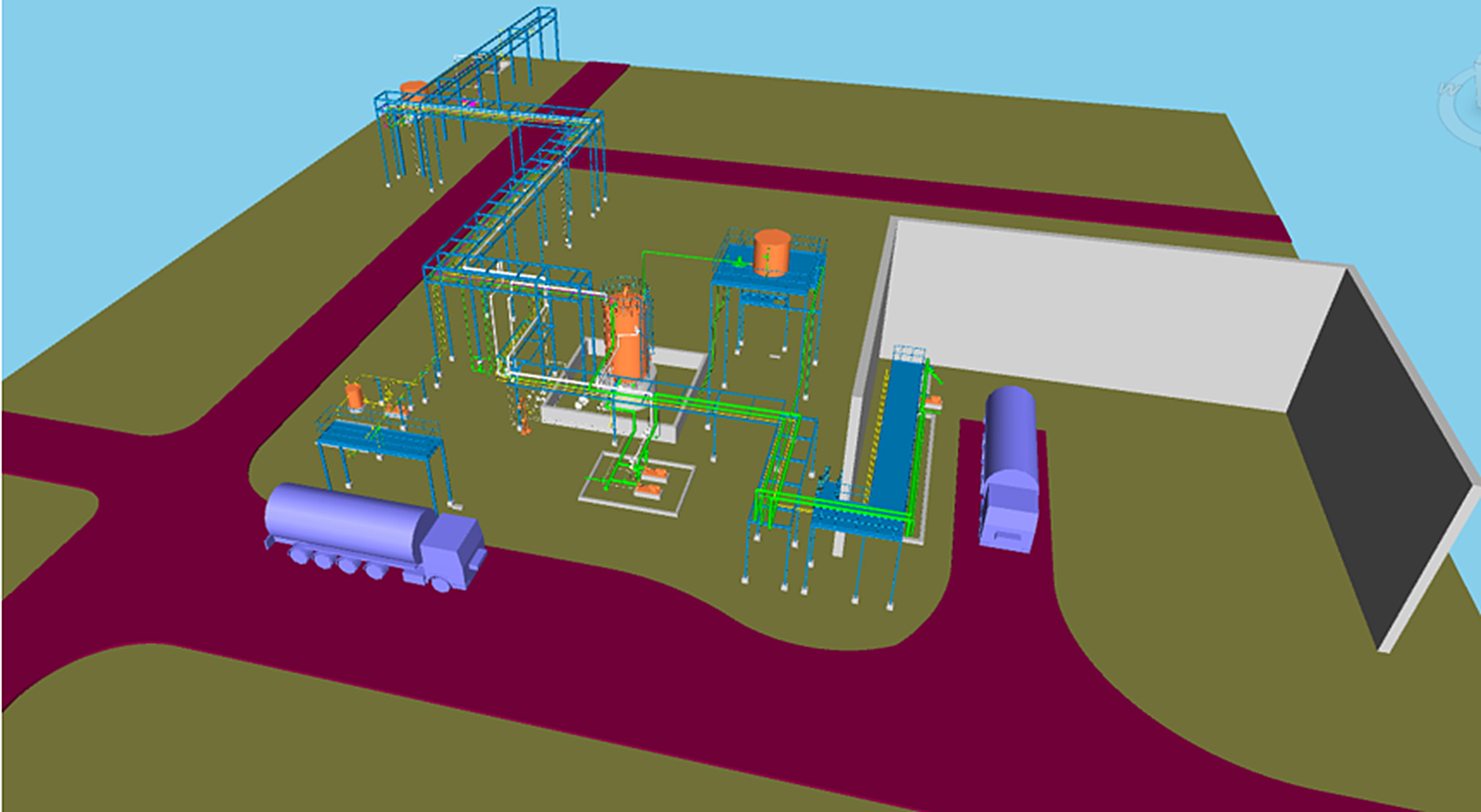

Project: Sulphonated Naphthalene Formaldehyde (SNF) Plant

Scope of Work: Extended Basic Engineering, Detail Engineering (Process, Civil &Structural, Piping), Procurement Assistance, and 3D Modelling.

Our Projects

- PDH Plant Air Outlet Header Erosion Elimination

- Diversion of CGC condensate in EC plant

- Installation of chiller in CW circuit

- Stand by facility for Hot Boiling

- Stress analysis for evaluating PG Tapping Failures in Furnaces

- Stress analysis for FDF turbine HP inlet steam line

- Stress analysis for 48" GRP flue gas line

- DEP for bypass line from the spiral cooler 11E‐1007 to BA Reactor

- DEP for Butanol waste liquid permanent transportation

- HVAC study in air circulation in manufacturing excellence cubicles

- Deputation of Instrumentation Engineers

- Recovery of Hexane from Niro Dryer

- Stress Analysis of fin fan inlet 20" LP steam header

- Stress Analysis of Fin fan LP steam condensate 10" outlet header

- FEED for Installation of a standby 1st flash vessel pump

Year

- 2018

- 2018

- 2018

- 2018

- 2019

- 2019

- 2019

- 2019

- 2019

- 2019

- 2019

- 2019

- 2019

- 2019

- 2019